Back in April, our Kittyhawk team was approached by a group of researchers from the University of California, Irvine (UCI) seeking assistance with a project exploring new approaches to advanced manufacturing. Building on a previous collaboration with Cal Poly Pomona, the students requested Hot Isostatic Pressing (HIP) support for several maraging steel samples produced through Laser Powder Bed Fusion (LPBF) additive manufacturing. We were happy to lend a hand with a HIP run in support of their academic research effort.

The Advanced Manufacturing Initiative

This UCI research is part of a broader Advanced Manufacturing project designed to explore how new materials can perform under extreme conditions:

“Additive Manufacturing, particularly Laser Powder Bed Fusion, offers a promising path forward. With rapid cooling rates (~10⁵–10⁶ °C/s) and steep thermal gradients, LPBF creates a highly non-equilibrium environment that broadens the microstructural design space and enables novel strengthening mechanisms in steels.” – UCI Report

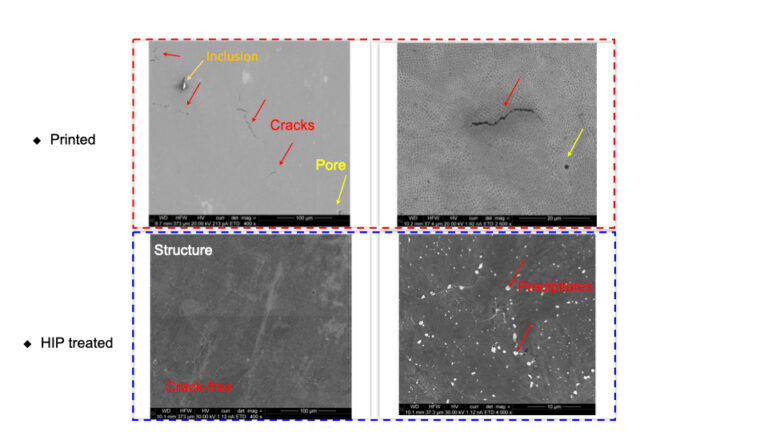

Using LPBF, the team 3D-printed maraging steel samples with complex internal structures. While the process offers incredible control, it can also leave behind tiny pores or imperfections that affect the material’s strength. That’s where HIP comes in. By applying high heat and uniform pressure, the HIP process can further refine the material and minimize printing defects.

Application of Hot Isostatic Pressing

Following the HIP run, UCI reported that the treated samples were nearly free of pores and cracks, confirming the success of the process. While the team also noted microstructural changes due to the high processing temperature, these results provided valuable insights for future developments.

microstructure imagery from the final report

“Kittyhawk brings proven expertise, advanced technology, and tailored solutions for manufacturers. Their deep experience in minimizing defects in 3D-printed parts, combined with well-optimized HIP parameters, made them an ideal partner for this effort. We also greatly appreciated their responsiveness and outstanding service throughout the process.

The successful integration of AM and HIP in this project may pave the way for scalable production of high-performance alloys for critical applications.” – UCI Report

By sharing real-world expertise and access to state-of-the-art HIP equipment, Kittyhawk is proud to support university-level research that advances material science and the next generation of additive manufacturing technologies.

Collaborations like these remind us that innovation happens when we work together toward better solutions. We’d like to thank the University of California, Irvine team for reaching out and trusting us with their research. We look forward to seeing where their efforts lead next.

About Kittyhawk

Questions?

Give Us a Call:

714-895-5024

California

11651 Monarch Street

Garden Grove, CA 92841

Oregon

301 S Redwood Street

Canby, OR 97013

4322 Marion Street SE

Albany, OR 97322

Navigation

© 2025 Kittyhawk Inc. | Designed by MOONCRUX