When Kittyhawk first expanded to Oregon, our goal was strategic: to reduce freight bottlenecks from winter storms, improve production in the Pacific Northwest, and better serve customers in aerospace, space, medical, and other advanced manufacturing sectors. The Canby facility officially opened its doors in 2019, but the vision behind it has been nearly 40 years in the making. They’re a small team making a big impact in Hot Isostatic Pressing (HIP).

Built with Purpose

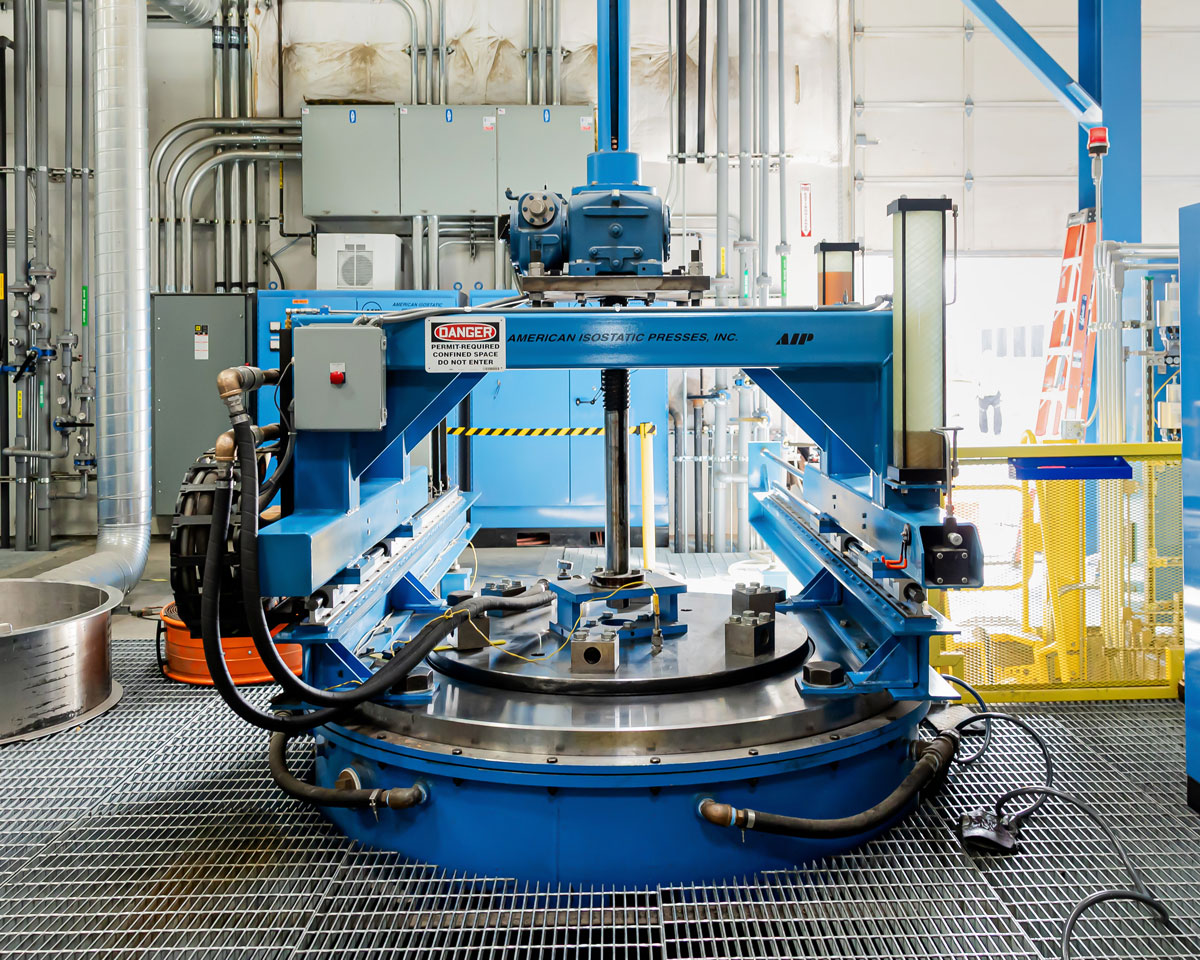

While Canby may be one of the newest Kittyhawk facilities, it’s also one of the largest: spanning 27,000 square feet. Kittyhawk purchased the extra space with a clear vision to grow alongside our customers. The site launched with two of the company’s largest HIP vessels at the time (each 46 inches in diameter) capable of processing large castings and supporting the demanding needs of advanced manufacturing.

Operations Manager Ramon Martinez has been with Kittyhawk for 20 years and was instrumental in getting Canby off the ground. “I came from our Southern California location and helped oversee the install, staff the team, and establish operations from scratch,” Ramon reflects. “I’ve worn every hat.”

While the Albany, OR now holds the largest single HIP vessel in the fleet following Kittyhawk’s acquisition of Stack HIP, Canby currently has the most available capacity of all Kittyhawk facilities. Growth has been steady, with new hires expanding capabilities across departments and second shift operations now in full swing.

Big Responsibilities

With a team of just over a dozen, including operators, quality personnel, drivers, and support staff, the facility operates across two shifts and is building toward a 24/5 production model.

Ramon has taken a hands-on leadership role rooted in his years of experience across every department. “Production is my strong suit,” he says, “but I try to guide the team wherever I’m needed. My goal is to help each department grow in a way that matches Kittyhawk’s standards, so that no matter which facility you’re in, the process feels seamless.”

Ramon Martinez

Operations Manager, Canby

Ryan Tout

Quality Manager, Canby

Alongside the leadership of Operations Manager Ramon Martinez, the Canby facility’s success is also credited to Ryan Tout, Quality Manager, who also got his start in California. Since joining the team, Ryan has helped formalize and strengthen the quality program and been pivotal in maturing the facility’s certification and inspection processes. Another key contributor is Eli Escobar, Quality Associate, who joined Kittyhawk straight out of high school and quickly advanced to be an integral member of the quality team.

For Ramon, leadership is just as much about culture as it is about delivery. “I try to be relatable, light-hearted—but focused. It’s important that people want to work here. That’s how you build a team that gets things done.”

HIP Capabilities

Canby operates several high-capacity HIP vessels. The vessels are AIP units, consistent with the legacy systems used across Kittyhawk, enabling Canby to share troubleshooting insights and processing workflows with ease. “Between us and Albany, we’re heavily titanium-focused,” Ramon explains. “Casting is definitely the most common manufacturing method we handle here.”

With standardized procedures across locations, the Canby team collaborates closely with Albany and our Garden Grove, CA headquarters to maintain product quality and deliver some of the best turnaround times in the industry.

Future Focused

With space already available for future bays and equipment, Canby is ready for what’s next. The plan? Add additional HIP vessels to meet further demand and continue expanding the team and schedule.

“We’re growing carefully and consistently,” Ramon says. “We want to build this out into a true 24/5 operation. We did it in Garden Grove, and we want the same here.”

The Canby Facility & Brandon Creason | President, Kittyhawk Inc

“The Canby facility represents exactly what makes Kittyhawk successful. Skilled people, great culture, and a focus on doing the job right,” said Kittyhawk President Brandon Creason. “Their dedication and hard work have made them an essential part of our operations in the Pacific Northwest.”

As Kittyhawk continues to invest in facilities like Canby, our mission remains the same in every location: deliver best-in-class Hot Isostatic Pressing with the speed, quality, and innovation that customers can rely on.

About Kittyhawk

Kittyhawk Inc. has been at the forefront of Hot Isostatic Pressing (HIP) since 1981, trusted by top aerospace and defense manufacturers to improve mission-critical components. With three West Coast facilities and some of the largest HIP vessels in North America, we deliver precision, reliability, and rapid turnaround times across industries like aerospace, defense, automotive, oil & gas, and more. We are AS9100 and NADCAP certified, ITAR and EAR compliant, and a CLASS 07 FFL holder, ensuring the highest standards of quality and service.

Questions?

Give Us a Call:

714-895-5024

California

11651 Monarch Street

Garden Grove, CA 92841

Oregon

301 S Redwood Street

Canby, OR 97013

4322 Marion Street SE

Albany, OR 97322

Navigation

© 2025 Kittyhawk Inc. | Designed by MOONCRUX